The Albany Advantage

Excellence and success in partnership

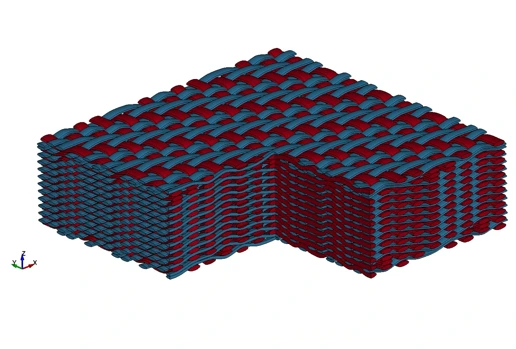

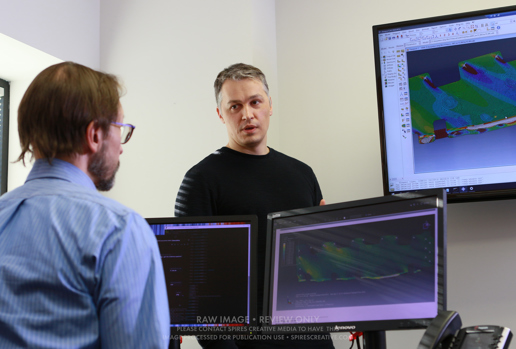

From initial concept of a new program requirement to the very last part shipped in support of it, Albany Engineered Composites (AEC) is our customers’ first choice to provide innovative technology and assembly solutions for their needs. Come experience the Albany difference for yourself.

Explore our expertise

Join the more than 4,400 employees around the world and let’s make something great together.

View our locations

99

%

On-time delivery

100+

years

Experience innovating composite material

9 Facilities

-

4 Countries

Our people make the difference

We'd love to hear from you

Let's work together and make great things