The faster speeds of today’s modern corrugators mean durable belt performance has never been more important. In fact, the word “DURA,” is built into the name of every corrugator product we sell, products that have earned Albany a global reputation for belt-making excellence.

From single-facers to double-backers, OEMs to retrofits, Albany has a belt for every application. Each is constructed of heavyweight, multi-layered fabric, heatset for stability and chemically enhanced to improve durability and resist contamination. The result: virtually indestructible belts designed to deliver consistent performance and value over remarkably long service lives.

COATED DURA-DRIVE™ LAGGING EZ

|

Designed to be installed quickly without glue.

This innovation is a result of assisting our customer through many long days installing lagging over the years. The seamed, glueless design will enable customers to install lagging in a fraction of the time currently required. Utilizing the well-established DURA-DRIVE™ LAGGING product as a base, we applied a coating of DURA-GRIP™ to provide ample frictional hold on to the drum and belt.

The base of the COATED DURA-DRIVE™ fabric is heat stabilized for strength and chemically treated for fiber bonding and abrasion resistance. The DURA-GRIP™ coating is a proven performer. Available in widths of 18.5”, 20”, 22.5", 25.5” and 28” and in lengths specific to the application and pre-seamed, COATED DURA-DRIVE™ LAGGING EZ will cover any typical machine. It is manufactured in a nominal thickness of .180” (Style 2203.), and can be adjusted as required. |

DURA-DRY®

|

Designed to Deliver an Extra Measure of Performance

Constructed of a 4-layer woven base and 100% polyester fibers and yarns, DURA-DRY® 2000 is tough enough to withstand the heat and stress of today’s modern double-backers, yet permeable enough to allow rapid drying. Our patented processing technique and excellent seam-to-belt uniformity provides an extra measure of safety against board marking. In addition, the belt’s mechanical and chemical processing have been optimized for improved durability, caliper retention and resistance to contamination. It allows excellent pressure transfer on all systems, eliminates stretching and contraction, and is more resistant to thermal degradation. |

DURAGRIP®

|

Patented Coating is Key to Preventing Slippage

Transporting board from the glue station to the stacker without crush on beltless machines requires a belt with a higher coefficient of friction than standard belts can offer. DURAGRIP® was developed for just this reason. An enhanced blue, ultra-tough, impermeable coating has been applied to the board side to increase friction and ensure positive transport of board regardless of machine configuration or auxiliary equipment. |

DURAGUARD™

|

Specially Formulated Surface Means Improved Edge Wear

The newest member of Albany International’s world-recognized “DURA” family of corrugator belts, DURAGUARD™ is constructed of a 4-layer woven base and 100% polyester fibers and yarns. Its surface is treated with Albany’s specially formulated coating, designed to virtually eliminate starch build-up while providing excellent durability against edge wear, the primary cause of top belt replacement. Available completely coated as a top belt for narrow runs or an optional 20” edge coating for wider runs, DURAGUARD’s durable, cleaner-running surface can improve production and increase board quality in a variety of operating environments. |

DURAGRIP-LP® / DURAGUARD-LP™

|

Faster speeds and higher temperatures of today’s corrugators mean the durability of your belts is critical. Albany International has enhanced two of its most versatile belts and designed them to run together on the same machine. Uniformly calipered for maximum compatibility and performance, Albany’s new Duraguard-LP and Duragrip-LP belts can help you attain maximum production by eliminating the speed differential that results from running mismatched top and bottom belts. With Albany’s special “package” pricing, you can receive premium value while enjoying the long-lasting performance you have come to expect from the global leader in corrugator belts. Call your Albany sales representative or the service center nearest you today to place your order or to learn more about how Albany’s new S-Belts can help you achieve — and exceed — your most ambitious production goals. |

DURA-DRIVE® LAGGING

|

Designed to Prevent Belt-to-Pulley Slippage

Designed especially to prevent belt-to-pulley slippage on today's high-speed corrugators, DURA-DRIVE® LAGGING is constructed of two layers of 100% synthetic fabric and manufactured with the same high-tech fibers and yarns as DURA-DRY® 2000. The fabric is heat stabilized for strength and chemically treated for fiber bonding and abrasion resistance. Available in widths of 18.5”, 20”, 22.5", 25.5” and 28” and in lengths of 20’, 40’, 60’, 80’ and 100’, DURA-DRIVE® LAGGING will cover any typical machine. It is manufactured in a nominal thickness of .180” (Style 2203. |

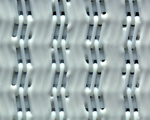

DURASPIRAL®

|

Save energy and reduce costs

With a more open belt, and a non- marking seam, DuraSpiral has shown to dramatically reduce the costs associated on a corrugator machine. Unlike woven belts, coated DuraSpiral has a construction that provides a large smooth contact surface while retaining open areas to allow moisture to pass through it reducing energy cost. It has also proven to reduce glue usage as well as reduce drive-load amperage. The coating provides a unique surface characteristic that improves the belts ability to grip the paper and help facilitate it through the double backer zone. |

CONNECTING OR LACING CABLES

Two lacing cables are supplied with every belt. Constructed using a plied stainless steel core with a polyester and nylon blend covering for durability, each has a 10’ leader wire attached to a 10’ cable. Cable diameter is .094”.

|