Pushing the Boundaries of Composite Technologies

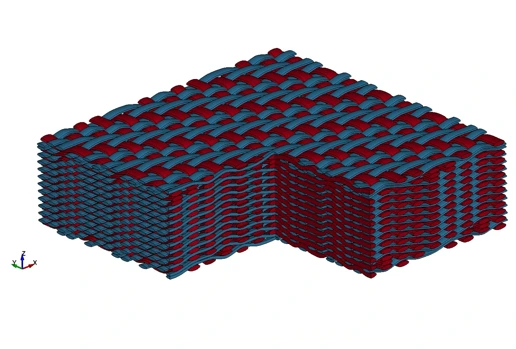

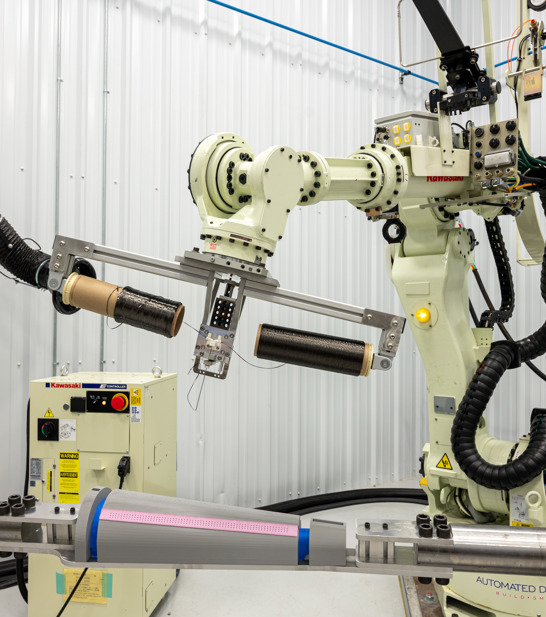

As a leading global provider of advanced composite, we focus and prioritize our investments in research and development to push the boundaries of composites technology. From new tools and software to improve our efficiency and effectiveness in our manufacturing operations to new product and materials development, we have over 900 patents and pending applications. Our proprietary processes and specialized materials are designed to provide exceptional strength, durability and corrosion resistance needed for harsher environments like aerospace.

Design, Testing and Assembly

Process Capabilities

Innovating our way to the top

We are at the forefront of advanced composite structures development and innovation. Whether a direct investment or as a collaboration with our technology partners and/or customers, we set the bar solving the most difficult challenges in composite structures and composite part integration. Collaboration with our customers for design, co-design, or process design on build-to-print products and assemblies enables our customers to be most successful.

Research Centers

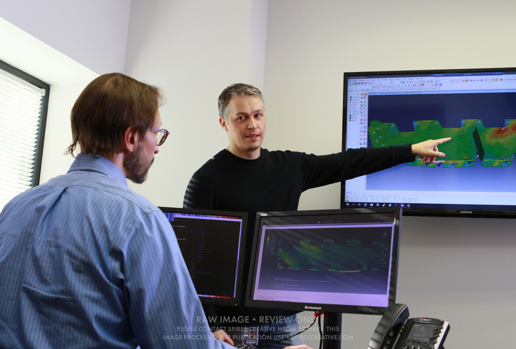

With a large staff of highly experienced engineers and technicians utilizing the latest equipment and resources, our research centers work independently and in partnership with our customers to develop new composite manufacturing processes, materials technologies, and design tools for easy conversion to production programs. Our dedicated technology centers have complete pilot and prototyping capabilities and each operation supports local and global development activities.

Rochester, NH, USA

Albany Engineered Composites (AEC) is headquartered in Rochester, New Hampshire, housing both research and technology activities alongside production facilities. As a subsidiary of Albany International Corp., AEC is committed to delivering exceptional products and services, prioritizing the highest quality and reliability standards.

The Research & Technology (R&T) Center and Rochester Operation comprise a cutting-edge 45,000 ft2 facility exclusively focused on fabrication and product development. With a dedicated engineering team, R&T is at the forefront of developing new and emerging technologies. Additionally, the center houses AEC's 3D composites simulation development team.

Salt Lake City, UT, USA

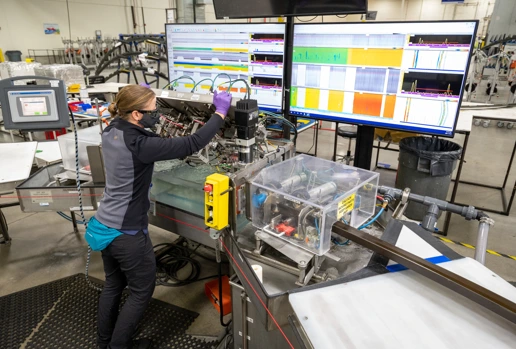

AEC's Salt Lake City operations consist of two manufacturing facilities covering 600,000 ft2. They offer comprehensive design, analysis, and manufacturing capabilities, supporting new and current programs from concept to integration.

With a strong history in design and build activities, they excel in key capabilities like assembly, hand lay-up, fiber placement, complex braiding, RTM, VARTM, and CVM. Salt Lake also supports rapid development and is an agile organization, accommodating changing customer requirements throughout design and development phases.

We'd love to hear from you

Let's work together and make great things