Advancing Composite in Missiles

Composite structures in missile fuselages offer a groundbreaking advancement in aerospace engineering. Combining high-strength fibers with a lightweight matrix material, composites provide exceptional strength-to-weight ratios. This results in increased missile performance, longer range, and improved payload capacity. The flexibility of composites allows for intricate shapes and enhanced stealth capabilities. Additionally, their resistance to corrosion and fatigue ensures long-lasting reliability and reduced maintenance. With excellent energy-absorbing properties, composites enhance missile survivability and effectiveness in hostile environments. This innovative technology marks a significant leap in missile design, optimizing performance and revolutionizing modern warfare.

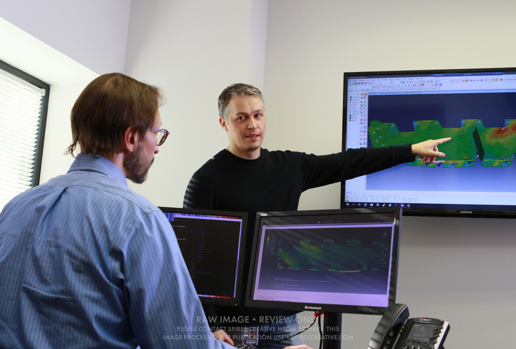

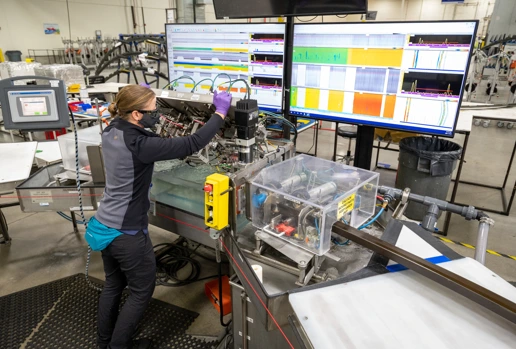

Unparalleled Proficiency in Composite Fuselage Production

When it comes to the production of the missile fuselage, AEC's proficiency in composite fabrication is unparalleled. The use of braiding technology allows for the creation of complex and precise shapes with optimal strength-to-weight ratios, ensuring the missile's structural integrity while keeping its weight to a minimum. The fusion of AEC's expertise in braiding, resin transfer molding, and vacuum-assisted resin transfer molding creates a formidable synergy, enabling the company to excel in crafting advanced composites for the JASSM missile. As a result, the missile's fuselage is strengthened to withstand the rigors of flight and deliver unmatched performance on the battlefield.

JASSM: Cutting-Edge Precision Standoff Missile

Albany Engineered Composites takes pride in introducing the JASSM, a cutting-edge 2,000lb autonomous, long-range, air-to-ground, precision standoff missile. This exceptional weapon is purpose-built to neutralize high-value, well-defended, fixed, and re-locatable targets on the battlefield.

We'd love to hear from you

Let's work together and make great things