Excellence and success in partnership

From initial concept of a new program requirement to the very last part shipped in support of it, Albany Engineered Composites (AEC) is our customers’ first choice to provide innovative technology and assembly solutions for their needs. Come experience the Albany difference for yourself.

Explore Our Expertise

Join the more than 4,400 employees around the world and let’s make something great together.

View our locationsOn-time delivery

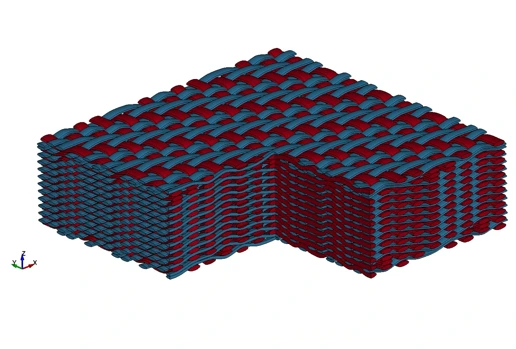

Experience innovating composite material

4 Countries

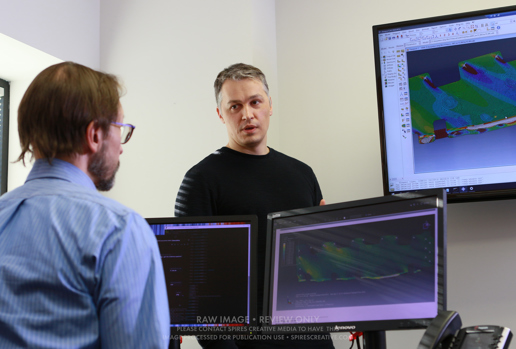

Our people make the difference

Designing and developing for the next generation

Our people are the driving force behind the future of aviation. With a relentless pursuit of excellence, we're shaping the next generation of aircraft. Our team's passion fuels the development of cutting-edge processes and capabilities, propelling us towards new heights in aerospace innovation.

Building and assembling advanced structures and components

Our people are more than a team. They are the backbone of unparalleled support. With a commitment to excellence, we deliver not just products but a promise of quality. Our dedicated professionals ensure seamless support for our customers and partners, setting the standard for excellence in every interaction.

We'd love to hear from you

Let's work together and make great things