High volume, large structure, continuous fiber placement, reduce waste

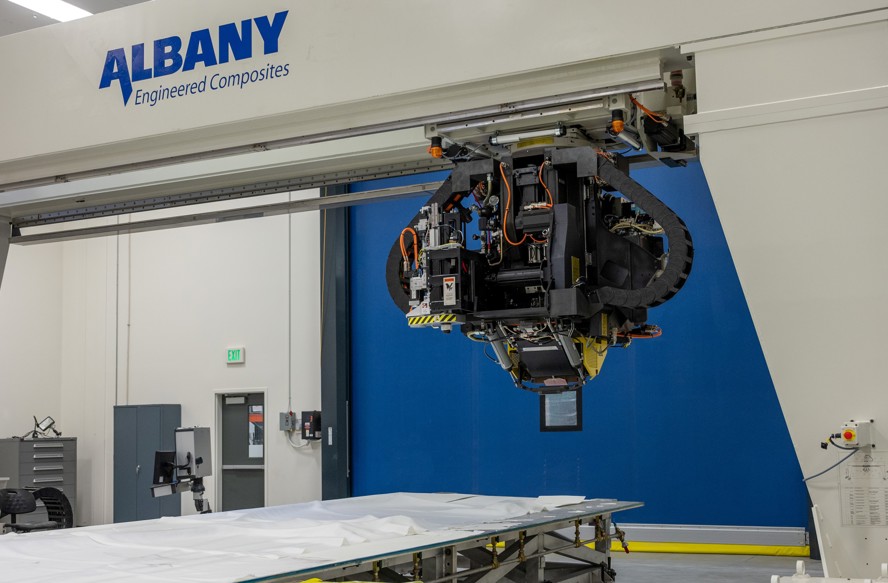

Automated Tape Lay-up (AFP) is used to precisely and repeatably place pre-impregnated tape material on large, complex geometry molds. AEC uses the AFP process to manufacture empennage skins and other structures on molds up to 50 feet and length and 14 feet in width. With the capability to place and cut unidirectional tapes 3” to 12” in width, AEC has the capability optimize the structural performance at efficient material deposition rates.

Automated Tape Layup: Precision and Efficiency in Composite Manufacturing

AEC engineers have decades of experience in ATL process design and development and utilize state-of-the-art process simulation software to develop and validate machine programs prior to running the programs on the ATL machines. This capability allows for Design for Manufacture/Assembly (DFMA) and Producibility assessments to be completed prior to part design release.

AFP technology facilitates the effective and repeatable manufacture of large engineered aerostructures parts.

We'd love to hear from you

Let's work together and make great things