High volume, large structure production

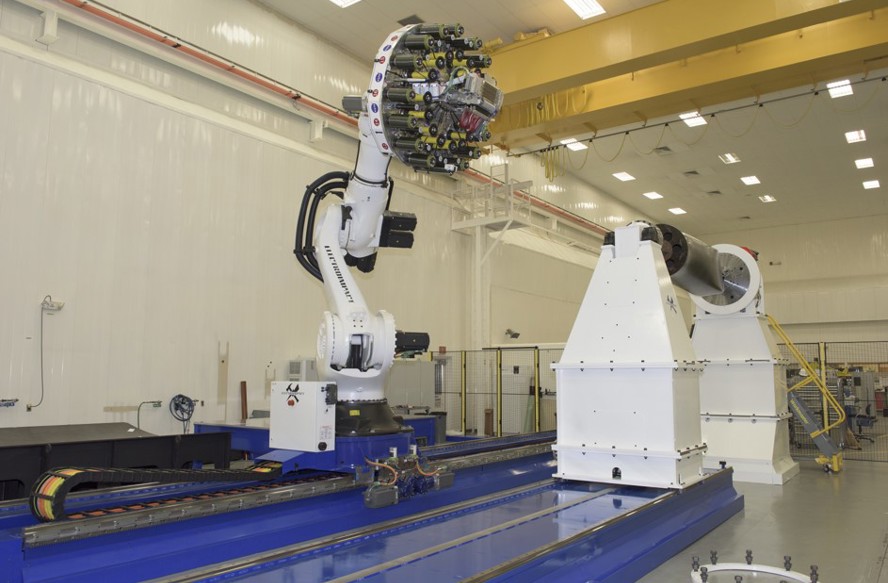

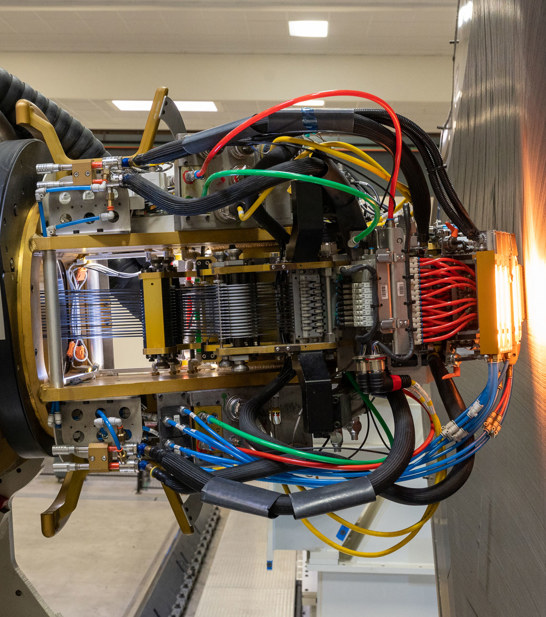

Automated Fiber Placement (AFP) is used to precisely and repeatably place pre-impregnated slit tape material on large, complex geometry molds. AEC uses the AFP process to manufacture wing skins and other structures. With the capability to place and independently control 32 individual fiber tows, each 1/8” wide, material can be placed and steered to optimize the structural performance and weight of the structure. Each tow can be individually fed, clamped, cut and restarted. The AFP machine head design can accommodate fiber placement in tight radii and over honeycomb core.

The Power of Automated Fiber Placement

Using a dual-head, stock-tail configuration, allows two molds to be loaded in the machine at the same time, allowing personnel access to one mold for manual operations and inspections while the machine is placing fiber on the other mold. This configuration helps AEC maximize the utilization and throughput of the AFP machines.

AEC engineers have decades of experience in AFP process design and development, and utilize state-of-the-art process simulation software to develop and validate machine programs. This capability allows for Design for Manufacture/Assembly (DFMA) and Producibility assessments to be completed prior to part design release.

We'd love to hear from you

Let's work together and make great things