RTM & CVM in Aerospace Applications

Resin Transfer Molding (RTM) and Controlled Volume Molding (CVM) are a core capabilities that AEC use to manufacture advanced complex shapes components for the aerospace industry. In RTM, a liquid resin is infused into a preformed dry fiber structure to create high-performance composite parts. AEC's expertise in RTM ensures that aerospace applications benefit from lightweight, durable, and precisely engineered components. With a focus on precision, quality, and efficiency, AEC's RTM capabilities play a pivotal role in shaping the future of aerospace engineering.

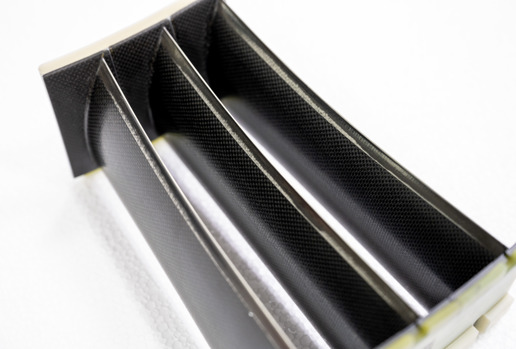

High temperature engine components

Resin Transfer Molding is widely used in to product aircraft engine components. These components are engineered to withstand high temperatures and harsh operating conditions. AEC manufactures a wide range of composite components for various commercial and defense applications.

CVM

Controlled Volume Molding (CVM) is similar to RTM except that a prepreg preform is used in the place of the dry preform. These close mold processes provide the ability closely control both the inner and outer surfaces of a part, while completing cure outside of an autoclave. CVM processing allows for the same controls of RTM while facilitating the use of approved material allowables for autoclave cure prepreg materials.

We'd love to hear from you

Let's work together and make great things