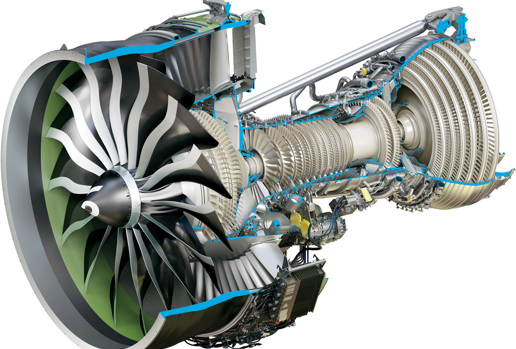

Essential for modern aviation

Composite fan blades are a key feature of this engine and an enabling technology with respect to fuel efficiency, cost efficiency, and innovation. The fan blade manufactured AEC is key to the success of the LEAP program. The LEAP engine offers exceptional fuel efficiency, reduced emissions, and enhanced performance, setting new standards for the aviation industry..

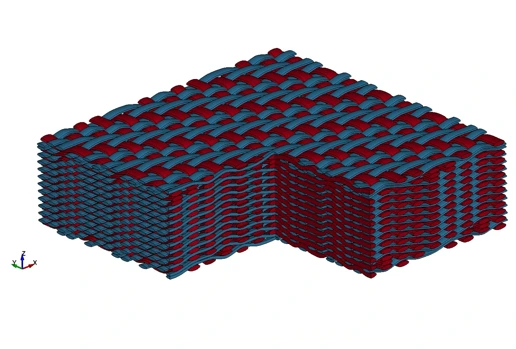

AEC 3D Woven Composite

AEC and Safran have developed 3D composite fan module components for the LEAP™ aircraft engine. The LEAP engine is a product of CFM International, which is the world’s leading supplier of commercial aircraft engines and a 50/50 joint venture between Safran and GE.

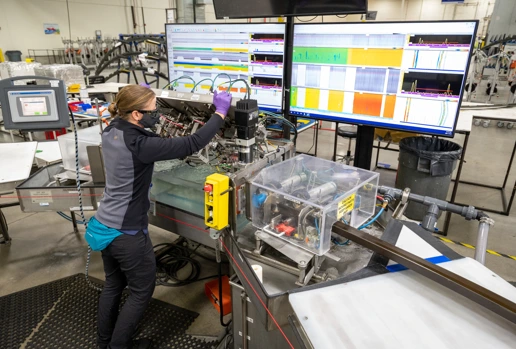

Resilient and Cost-Effective Innovations

The 3D composite architecture provides a structure that is highly damage tolerant and able to withstand significant in-plane and through thickness loads, enabling the composite blade to withstand birdstrike. Additionally the automated processes used in 3D composite manufacture are more reliable and cost effective than a conventional laminated blade fabrication process would be, as less manual labor is required to fabricate the blade.

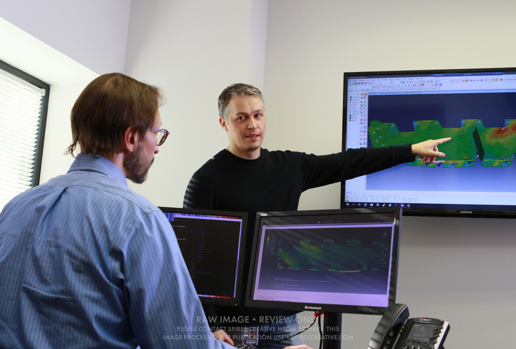

Technical Capabilities

We'd love to hear from you

Let's work together and make great things