CH-53K Tail Rotor: Advanced Helicopter Technology

Composite materials have revolutionized helicopter tail rotors, offering exceptional strength and reduced weight. Carbon fiber reinforced composites, often used, provide high structural integrity and improved aerodynamics. These advanced materials enhance rotor performance, increase fuel efficiency, and contribute to quieter and smoother flights, elevating the overall helicopter experience. AEC brings the expertise in design, manufacture and assemble the helicopter empennage.

A key partnership

As a key partner to Sikorsky, AEC manufactures critical components for the CH-53K helicopter, including the tail rotor assembly, aft assembly, and sponsons. Leveraging advanced composite technologies, AEC ensures the production of lightweight, high-strength components, contributing to the CH-53K's exceptional performance and reliability as a cutting-edge heavy-lift rotorcraft.

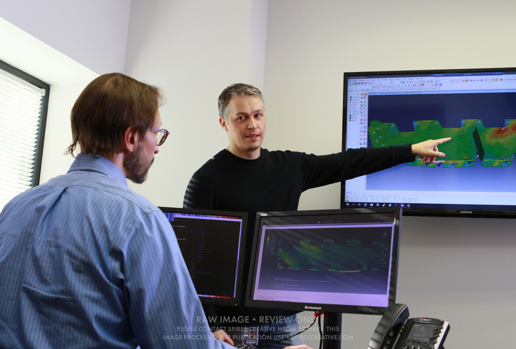

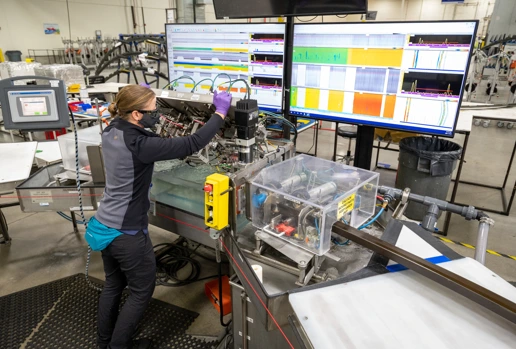

Focus on quality and delivery performance

AEC's manufacturing prowess extends to its Salt Lake City facility, where key sections of the CH-53K helicopter are being produced with utmost precision and excellence. This dedication to excellence is further enhanced by AEC's unwavering focus on delivery performance, meeting project timelines and enabling Sikorsky to advance with its CH-53K program. As a key partner to Sikorsky, AEC's Salt Lake City facility plays a pivotal role in the success of the CH-53K program. Their expertise in composite manufacturing, combined with stringent quality controls, results in lightweight, durable, and reliable components that enhance the CH-53K helicopter's capabilities and mission readiness. This collaborative effort reinforces AEC's position as a trusted and valued partner in the aerospace industry, solidifying the foundation for future innovative endeavors.

Technical Capabilities

We'd love to hear from you

Let's work together and make great things